Vertical L-Type Props

Related products

In H-type models, achieving vertical alignment is possible thanks to two spheroidal cast iron bushings that either increase or decrease the extension. This model is produced in two variants: H1 and H2.

H-type vertical props distinguish themselves from other classes by their method of vertical alignment adjustment. This is achieved using two bushings that increase or decrease the extension of the prop.

GBM manufactures two types of H supports: H1 (with a smaller diameter) and H2 (with a larger diameter). Both versions feature:

- Adjustable length from 1.80 to 5.40 meters, depending on the support model, with a 10 cm increment, using the adjustment of two steel bushings;

- Guaranteed tension of 38.00 kN, regardless of the applied extension;

- Anti-shearing system: increased length of the inner tube compared to the outer tube ensures at least a 10 cm difference between the two tubes during the closing phase, preventing accidents;

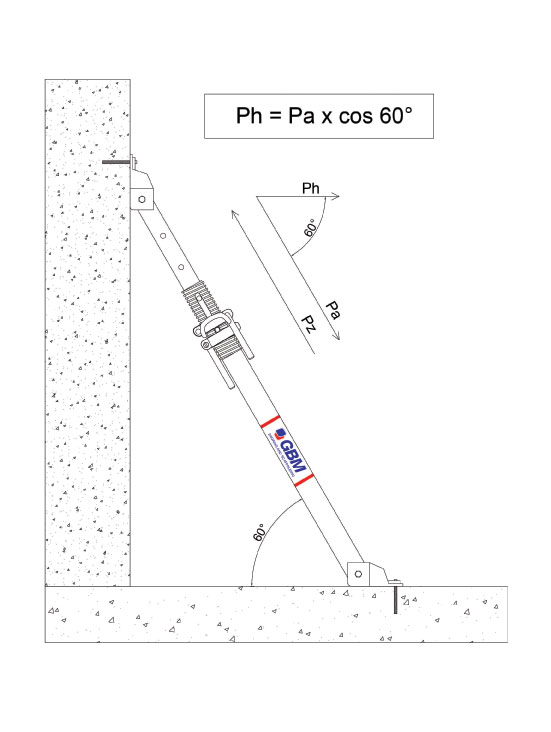

- Plates mounted on hinges at both ends ensure better adherence, allowing the prop to be fastened and assembled at various angles;

- Tube protection: hot-dip galvanizing according to UNI EN ISO 1461; minimum guaranteed thickness of 55 microns;

- Inner tube diameter 63×2.60 mm;

- Outer tube diameter 76×2.60 mm.

Available upon request:

- Customized label with the client’s logo, including information about load capacity and maximum extension.

Properties of the props:

- Guaranteed tension: 38,00/41,90 kN;

- Inner pipe diameter: 63×2,60 mm;

- Outer pipe diameter: 76×2,60 mm.

Properties of the props:

- Guaranteed tension 38,00 kN;

- Internal pipe diameter 48×3,00 mm;

- Pipe diameter 60×2,50 mm.

L1-type push-pull prop, the lightest support, is typically produced in a painted version to optimize the cost-to-benefit ratio since it is used for supporting objects of low mass.

L1-type push-pull prop, the lightest support, is typically produced in a painted version to optimize the cost-to-benefit ratio since it is used for supporting objects of low mass.

Characteristics of the L1-type push-pull prop:

- Tube protection: immersion-coated paint layer, in red color RAL 3009, with a minimum durability according to the standard test ASTM D 2247-87 in a humidity chamber;

- Inner tube diameter: 48×1,80 mm;

- Outer tube diameter: 56×1.65 mm;

- Adjustable length from 1,80 to 5,00 m, depending on the support model, with a 10 cm increment, using the double-handled collar;

- Guaranteed tension of 22,00 kN, regardless of the applied extension;

- Anti-shearing system: increased length of the inner tube compared to the outer tube ensures at least a 10 cm difference between the two tubes during the closing phase, preventing accidents;

- Plates mounted on hinges at both ends ensure better adherence, allowing the prop to be fastened and assembled at various angles.